LATHE CUT RECORDS - VINYL LATHE CUTS

Lathe Cuts - No Minimum - Fastest Turnaround Time 2 Days

CALL 917-580-0052 BEFORE PLACING YOUR ORDER

Lathe Cuts - No Minimum - Fastest Turnaround Time 2 Days

CALL 917-580-0052 BEFORE PLACING YOUR ORDER

33 EP Lathe Cuts $13 Each Both Sides

Clear Lathe Cuts $10 Each Both Sides

Lathe Cuts Shipped In Clear Poly Sleeves

Black 7" lathe cut $11.00 Each Large hole

Dj Din Dell is demonstrating how to mix our embossed records made of black polycarbonate with out back tracking.

Using the "stop and go" method. It's not so easily done, but with practice you can nail it!

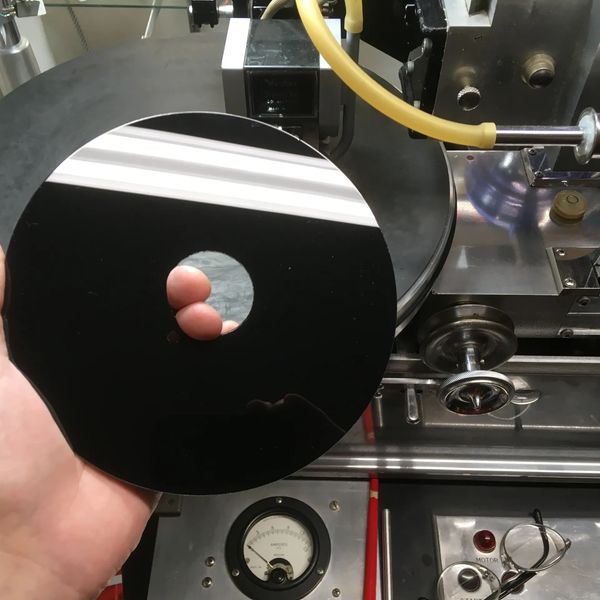

My lathe cuts starts out as a square polycarbonate 7.5" x 7.5" sheet, after the grooves are embossed, it will be trimmed round, it's cheaper to buy blanks that are square than round blanks.

THE BEST SOUNDING LATHE CUT RECORDS

What Is A lathe cut record?

Pressed records are mass-produced. Lathe cuts are made of POLYCARBONATE plastic and are cut individually one at a time. Pressed vinyl records on the other hand are made on a hydraulic press with two heated meatal stampers.

What is the difference between Stereo vinyl LP and lathe cut records?

Lathe cut vinyl are custom made by cutting grooves into a polycarbonate disc using a stereo record cutting lathe. Custom records are recorded very fast with no minimum at $10 each. Turnaround times usually 2 days.

Pressing plants require minimums of 200 plus. Each lathe cut vinyl is done in real time with a sapphire embossing stylus mounted on our Scully stereo cutting lathe. Inspection is given to each record and with my 50 years plus experience, I can make you the best sounding record every time.

How do they sound?

The sound reproduction is good as pressed vinyl records using my exclusive sapphire embossing stylus. My records are embossed with a sapphire cone stylus producing silent grooves having a full frequency range from 20Hz to 14Khz. High frequencies at 15Khz to 20Khz may be filtered out depending on the type of music you provide.

Never A Setup Fee For Short Run lathe cut vinyl records:

Each custom lathe cut record starts out as a square, then it is trimmed into a 7 inch disc, after it's recorded this is the way I do them. Others use round blanks for the ease and convenience, but at a higher cost per disc. I manufacture my own blanks and sapphire embossing styli, passing the saving on to you at only $10 each and 33 rpm at $12 each.

12" inch LP Lathe Cuts:

I do not stock 12" blanks for economic reasons and the time it takes to produce each one.

On the other hand, 7 inch record, are more practical. I only specialize in making 7" records.

I can make a 12" inch lathe cut record, no problem, But I'm very RELUCTANT to do so. The reason is, some audio files may have different EQ, or vocal sibilant problems and levels.

Doing a 12 inch records also involves listening to all the audio files before setting the levels, lines per inch for the cutting lathe. Also I don't stock sleeves or covers for 12 inch records.

12 inch records have to be cut from a large 4' x 8' sheet of polycarbonate and has to be cut down again to 13.5 inch squares then trimmed round after it's recorded.

Lathe Cut Records Vs Vinyl Pressings:

Many call them vinyl pressings, but they are not, they are embossed records and vinyl records are pressed, made with two hot steam heated metal stampers installed in a hydraulic pressing machine. I specialize in embossing 7" inch discs that are made from clear or black polycarbonate plastic.

Vinyl And Polycarbonate:

LP albums and 7 inch 45 rpm records, are pressed, and polycarbonate records are not. They are cut one at a time.

Embossed Short Run Lathe Cut Record Pros:

Cost for 7" record $10 per disc single sided or both sides. Cost for 7" inch record 33 rpm $12 per disc. Single sided or both sides, and very affordable. Less expensive than lacquer and diamond cut. Excellent audio quality 20Hz-14Khz Very low surface noise at - 40db Good silent grooves. Good enough for Jazz and Classical music. Great for for one-off short runs.

Embossed Short Run Lathe Cut Record Cons:

Embossed short run lathe cut record have to be recorded in mono and not in stereo. They are not as loud as a pressed 45 vinyl record, otherwise it will skip if recorded louder and in stereo. Embossed records are not recommended for DJ work or DJ scratching and very tricky to cue, and will not play backwards. A warned out stylus will also skip.

Lacquer & Diamond Cuts - Pros:

Stable groove tracking - Excellent audio quality - Louder cuts - Good stereo separation lower surface noise at - 65 db can be cued and plays backwards, and very expensive. Lacquer discs are made only in Japan and are very expensive and I don't stock them.

Jukeboxes:

I don't recommend playing embossed records in Seeburg, Rockola, and Wurlitzers with the Cobra Tone Arm. Rowe AMI JBM and later from 1963 and up will play embossed records.

Lacquer Acetate Disc:

The aluminum lacquer coated discs, also made one at a time, using a stereo or mono cutting. This method has long been used for producing lacquer masters, which are then used to make metal stampers for pressing vinyl.

Scully Machine Company Bridgeport Connecticut:

Most of the Scully lathes used for this purpose were manufactured pre -1960. These machines were used in the production and manufacturing process for vinyl records. Cutting a lacquer master discs, was then electroplated to make the metal stampers used by the pressing plants.

The Difference Between Plexi, Polycarbonate And Lacquer acetate:

Polycarbonate plastic is not to be confused with Plexi Glass. Plexi can not be cut or embossed with a sapphire or diamond stylus. On the other hand a lacquer disc can only be cut with a sapphire stylus, it is not possible to embossed lacquer.

Stereo HI-FI Lacquers can be in stereo or mono, a lacquer done with a stereo cutter head will result in a great stereo playback. Embossing polycarbonate lathe cut records with a stereo cutter head will result in a MONO play back with a very small amount of stereo separation and it will skip badly when playing it back.

De-Essing:

Sibilant Vocal Tracks De-essing Is any technique intended to reduce or eliminate excessive highs in the recording or the prominence of sibilant consonants, such as the sounds normally found in the vocal track by "s" and "sh", in recordings of the human voice.

Sibilant frequencies lies anywhere between 2–10 kHz, depending on the individual's dental work. This causes havoc in cutting records. I'll throw in the Behringer 9024 Ultra-Dyne to clean up some sibilance.

Recommended cartridges:

Stanton, Audio-Technica, Shure, ADC, Etc. try different turntables if you have a skipping problem. Set the Anti skating for best results. Crosley or inexpensive turntables may or my not work with lathe cut records. A magnetic cartridge is more preferable. Embossed lathe cut records that are recorded louder tend to skip more. Playback stylus pressure no more than 3.5 grams.

There is a trade-off - Your Choice:

LOUDER CUT = The possibility for SKIPPING - SOFTER CUT = Lower volume = zero chance for SKIPPING. If your record skips try different turntables. NO DO OVERS and No refunds. 45 rpm records recorded longer than 4 minutes and 33 rpm longer than 6 minutes may skip during playback, therefore I will reduce the audio level to avoid this !.

Center Labels Are Not Provided.

Sending Audio:

CALL 917-580-0052 BEFORE PAYING AND UPLOADING AUDIO !

Zelle and PayPal email:

https://www.discogs.com/user/NY-Lathecuts

https://www.youtube.com/c/NewYorkLatheCuts/videos

https://www.instagram.com/nylathecuts/

https://www.facebook.com/nylathecuts

https://nylathecuts-com.webnode.page/

https://lathe-cut-records.wixsite.com/lathecuts

https://vinyl-pressing-plants.com/ny-lathe-cuts/

https://free-5497807.webadorsite.com/

Working Hours:

2pm est. - 12 midnight

Comparing lathe cut records to the actual audio wav file or mp3

Scully Lathe Built By Bridgeport Machine Co. In 1957

nylathecuts.com

917-580-0052